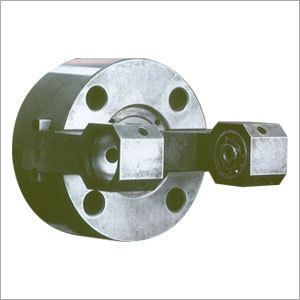

हाई स्पीड पावर चक्स

उत्पाद विवरण:

हाई स्पीड पावर चक्स मूल्य और मात्रा

- टुकड़ा/टुकड़े

- टुकड़ा/टुकड़े

- 1

हाई स्पीड पावर चक्स व्यापार सूचना

- 100 प्रति दिन

- 2-7 दिन

उत्पाद वर्णन

Our customers can avail from us premium quality High Speed Power Chucks. These power chucks are manufacture by our highly trained professionals in our huge infrastructure facility using high-grade alloy steel, obtained from the reputed vendors of the market. Offered power chucks are easy to operate as material removal, clamping and declamping is easy and time saving. Keeping in mind the wide demands of our clients, we are able to offer the High Speed Power Chucks in many specifications.

Other details:

Power chucks in 2, 3, 4, 5, 6, 8 and 12-jaw types are manufactured in close as well as hollow types.

Range

-

80mm to 1000mm in close centre type

-

135mm to 800mm in high speed hollow type

-

The chuck body is made of alloy steel-robust construction, the hard jaws, base jaws, wedge are case hardened and ground to suit customer needs.

Features

-

Front opening design saves cleaning and servicing time since chuck does not need to be taken off from spindle.

-

Clamping and declamping time is saved

-

Higher rate of material removal is possible

-

Keying time saved, hence operator fatigue is also eliminated

-

Repeatability maintained within 30 microns.

Technical Features

-

Body : Alloy Steel

-

Guide ways : Hardened and ground on all surfaces

-

Base jaws : Guided in deep, wide, hardened slots on the chuck body with serration on the top surface

-

Hard jaws : Case hardened and ground.

Specifications

| Chuck dia in mm | 135 | 165 | 210 | 250 | 315 | 400 | 500 |

| dia A | 135 | 165 | 210 | 250 | 315 | 400 | 500 |

| dia B | 30 | 39 | 52 | 70 | 95 | 130 | 140 |

| dia M H6 | 110 | 140 | 170 | 220 | 300 | 380 | 380 |

| D (PCD) | 82.6 | 104.8 | 133.4 | 171.5 | 235 | 330.2 | 330.2 |

| E x 3 nos. | M10 | M10 | M12 | M16 | M20 | M20 | M20 |

| dia F | 40 | 48 | 63 | 78 | 100 | 142 | 142 |

| G | M32x3 | M39x1.5 | M55x2 | M72x2 | M92x2 | M133x2 | M133x2 |

| H | 64 | 87 | 96 | 106 | 100 | 130 | 130 |

| a | 39 | 49 | 59 | 75 | 98 | 118 | 118 |

| b H 7 | 10 | 12 | 17 | 21 | 21 | 25.5 | 25.5 |

| I | 60 | 83 | 92 | 101 | 95 | 125 | 125 |

| C | 4 | 5 | 6 | 6 | 6 | 6 | 7 |

| J | 40 | 52 | 55 | 65 | 64 | 80 | 80 |

| Serration 90o | 1/16" | 1/16" | 1/16" | 1/16" | 1/16" | 3/32" | 3/32" |

| Jaw Stroke (On Dia) | 6mm | 10mm | 10mm | 11mm | 11mm | 12mm | 12mm |

| Min Engagement | 12 | 12 | 16 | 18 | 20 | 20 | 22 |

| Runout on chuck OD | 0.02 | 0.02 | 0.02 | 0.02 | 0.3 | 0.03 | 0.03 |

| RPM | 6000 | 5500 | 5000 | 4000 | 3000 | 2500 | 2000 |

| Max Drawtube Pull (kgf) | 2500 | 3000 | 4000 | 6000 | 6000 | 9000 | 9000 |

| Max Gripping Force (kN) | 50 | 60 | 80 | 120 | 130 | 200 | 210 |

| Weight (Kgs) | 5.8 | 7.5 | 16 | 26 | 38 | 90 | 150 |

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+